Last Updated on January 26, 2022

What Is The Minimum Order Quantity (MOQ)?

Long story short, the minimum order quantity (MOQ) is the smallest amount of items that can be purchased from a supplier. MOQ is widely used by companies outside the retail sector. MOQs usually reflect the economic complexity on the vendor’s side that is associated with order processing (for example, administrative tasks such as billing and bookkeeping) and their subsequent execution (for example, shipping and handling costs).

Complex MOQs that combine several constraints are encountered when economic complexity cannot be expressed with simple MOQs. Apart from MOQ, the most prominent limits include Economy Order Size (EOQ), ratios, and discounts.

Why Do Suppliers Have Minimum Order Quantities?

It’s very important to say that payments for the services of a logistics company or the cost of delivery often exceeds the purchase amount, which leads to forced underdelivery. As a result, grocery prices rise, store shelves are empty, and suppliers are forced to pay many small fines.

According to the words of a supplier who works on an online platform, due to different market forces, suppliers often cannot get the networks to detail mutual obligations and are forced to agree to all the terms of the standard contract.

Otherwise, the contract will not be signed, which, taking into account the current share of retail chains, is equivalent to the supplier leaving the business.

So, simply put, having MOQ helps suppliers do their job well for each customer and pay all expenses with the feeling that this business is really a business (with money earned and satisfaction obtained).

What Are the Benefits of MOQ’s for Wholesale Suppliers?

Wholesale prices are always lower than retail prices. However, you shouldn’t forget that different suppliers and companies have different prices for the same product. No company will sell to the detriment of its own interests.

Why is it more profitable to have a cooperation with a wholesale business?

Bulk purchasing has a large number of advantages, the main one is being economic. As already mentioned, wholesale prices are always lower than retail prices. But one can also save on delivery of goods: while ordering products via the Internet, one does not have to pay for delivery several times, paying for these services once upon receipt of a batch of goods.

Moreover, you save time because you can restock items once a month (or less often), rather than spending regular time placing things and waiting for delivery. And if you buy packing bags in bulk, then you will not have any problems with the packaging of goods at all.

Wholesales are great for stores both large and small. Thanks to this type of shopping, the goods will always be in stock and a buyer will not go to competitors offering faster delivery. Also, this option will be relevant for large orders of the same products to schools, kindergartens, etc.

Another advantage is the convenience of shopping. Most wholesalers sell their products online, so to place their order they just need to have an Internet connection and some money in their bank account.

You no longer need to go to dusty warehouses and take out products yourself. All this will be done by the supplier, and the goods will be delivered to the office of the carrier company or even to the doors of your warehouse, home or office.

What Impact Do Minimum Order Quantities Have On Your Inventory?

The order value affects the warehouse stock. Thus, if you as a supplier set a high MOQ, orders will be larger and inventory fluctuations will be more notable. On the other hand, if the MOQ is low, these inventory fluctuations will be less noticeable. So, MOQ has quite a big impact on the warehouse.

High Minimum order quantity

The impact of the high MOQs is quite understandable when you try to consider it a bit closer. It’s a very low risk of stockouts and lower administration costs, which is good, obviously.

Out of the worst things, it’s important to mention higher investment of working capital to reach good MOQ, very high holding costs, which can harden inventory management and increase a risk of obsolescence.

Low Minimum order quantity

Speaking of an impact of low MOQs, you can see a vice versa thing here: very low holding costs, a lower risk of obsolescence, because customers are frequently buying products, which can increase risk of stockouts (this can be bad and good at the same time).

Low MOQ doesn’t need a great involvement such as investments, which also can be comfortable for a seller at some point.

How To Calculate Minimum Order Quantity

The main purpose of MOQ is non-linear optimization. Despite the fact that the issue can be quite hard, on the practical side very good solutions can be found for it.

Concepts related to the general MOQ problem. We have:

- The name is directly related to the product. Usually the number of units of a product is expressed as an integer, but this is not a requirement.

- Order quantity for each item (can be zero) – reflects a possible solution to the MOQ issue.

- Economic benefit from each additional unit of each product.

- The cost of purchased goods. The aim is to maximize the profit from the budget and to increase the order volume, which is expressed in terms of costs. The purchase price of an item usually does not change, but it’s forbidden to rely on assumptions, so discounts must be taken into account.

On the Internet there are a lot of different websites where you can see a so called ‘formula of a Minimum Order Quality’, and some people can even say that they know algorithms of how to calculate it, but actually you should know, that there is objectively no specific formula, and every company has their own system of calculating and determining these digits.

1. Demand determination

Demand forecasts require an understanding of product type, competition, seasonal exposure, and many other factors in order to estimate unit sales for the future. This data can help sellers who think about inventory optimization to be informed about the next purchase order. The inventory forecast matches the supply and demand in the equation.

The MOQ determination (that is necessary to be given from the manufacturer), is similar to what one needs to sell. Also, it’s important to consider the overall schedule for preparing the inventory for shipment, such as lead times, time of delivery, pick-ups from your 3rd party logistics provider (3PL), and any possible delays. One may realize that in particular cases, one needs to get inventory (as well as keeping management software ready for work) as soon as possible.

2. Break-even point understanding

Setting a MOQ is essential; to do this one must figure out what the break-even point is. This is the number that is shown as soon as completing the second transaction for DTC (A Day ‘Til Cancelled order) is done. Usually it is when a seller recoups customer acquisition costs and a customer returns through email marketing efforts.

Speaking of wholesale pricing, considering the lowest dollar per unit cost the seller is willing to charge in exchange for a higher cost – is the first thing on the to-do list. Unless you pay for smaller numbers at a higher price, the cost cannot be that low when your profit margins are nearly zero – whereas bulk discounts are expected.

3. Considering inventory holding cost

Some products have higher storage costs, depending on size, storage duration and particular storage requirements. It’s very important how a seller can manage the fill rate in their storage. This can help any seller financially if such items are not kept in stock for too long.

The cost of holding inventory is the real cost of keeping all of the products. This is what every seller needs to understand before increasing order volume and investing heavy budgets in products and inventory. Minimum order quantity also has an impact here.

4. Suggesting a personal MOQ

Let’s come up with the following idea: a Seller’s product is constantly in very high demand. To make a profit, they need to sell at least 230 units per order, but the average order of their partners is about 250 units per one.

This Seller may set 250 units per order as the MOQ (or reduce it to 230) if their partners or customers have been buying 250 units in the past.

How To Make The Most Of Minimum Order Quantities

Minimum order policy can seem terrible for a customer, but it’s always great for a seller. Many e-commerce businesses work with manufacturers who have their individual MO requirements, and some brand names can implement their own MOQs through wholesale partnerships or minimum cost thresholds.

Let’s now speak about some ways to deal with MOQ.

Induce a higher spend

Speaking of the retail or wholesale business, sellers can be required to set a minimum total for bulk buyers to ensure that retailers pay the minimum amount. In exchange for the costs, sellers also have an opportunity to offer bulk discounts where they charge the retailer a lower unit charge in exchange for higher guaranteed total costs.

Every seller needs to remember that they try to establish long-term relationships with retailers – and just because someone wants the best deal doesn’t always mean it’s worth it.

By the way, suppliers can test this strategy for the direct-to-consumer deliveries by requiring a minimum amount of products to be sold (for example, 5 cans of a drink at $10 each to ensure your order value is at least $50) to cover the customer, acquisition costs and cost of goods sold.

It’s a good idea to try this with a free shipping cost threshold where suppliers have some requirements, that customers need to make some ‘cash flow’ to be qualified for free shipping.

Minimal SKU accounting

The important fact is, SKUs are issued only to those products that are in stock. Brands often have more SKUs than they should and have to pay storage fees and pay out of their own money to meet MOQs for products that are not sold (or being sold slowly) and are not generating revenue.

Simple and minimal SKU managing helps with inventory forecasting. 10 or 30 SKUs can be difficult to manage, so let alone 400 SKUs, which can be very complicated.

The use of new colors and variations in products is easily confused. Therefore, SKU counting is very important in e-commerce.

Increasing inventory turnover

Excess inventory stimulates suppliers to have a higher inventory turnover rate, which means they need to sell everything that is in storage sooner and faster because they have already invested money in advance. This is not to say that they need to do flash sales just to deplete inventory, but rather seek creative ways to attract and retain customers.

If the amount is too high and a seller has not yet proven their business model or product fit for the market, it is better to look somewhere else. Otherwise, they need to spend too much money that they may not be able to return, and also pay for warehousing.

Finding other distributors

If the manufacturer’s MOQ is higher than the buyer would like it to be, the latter one can always try to negotiate with the seller. It’s worth a shot. If the manufacturer does not look forward to bargain and still requires too high MO, one can consider working with a trading company or wholesale distributor, resellers who buy in bulk from the manufacturer and resell smaller groups of products to others.

Other issues

One can get creative in conversations with manufacturers and suppliers. There’s always a chance to rephrase the questions or try to think outside the box:

- Let’s see if the manufacturer allows their supplier to mix or order multiple different products to achieve a MOQ, not just the same units.

- Let’s ask the manufacturer if they have product leftovers from other customers who have canceled orders, and not require them to manufacture anything from scratch.

Focus on relationships

It’s good to start with good terms from a manufacturer, but it becomes even easier over time especially when suppliers want to build good relationships with them.

See how it works:

- A Supplier sells their manufacturer their vision of a product and becomes a partner

- Their e-commerce business keeps growing

- The manufacturer is happy as they keep making money alongside Seller’s growth.

- The Seller pays them on time and orders more from them.

- Over time, they may offer or agree on better conditions and be more flexible with the Seller.

How To Deal With Minimum Order Quantities As a Buyer

The minimum order quantity is the start button for any business relationship between a buyer and a supplier. No doubt, suppliers have an advantage at this point because MOQ provides them with financial benefits and that they cover their costs. However, MOQs can also benefit customers: they make it easier to compare prices, strengthen the customer-supplier relationship, and can help improve warehouse management (inventory management is a predictable and quite important thing).

FAQ

How do you find the minimum order quantity?

There is actually no standard formula for calculating the MOQ. To determine the right minimum order quantity for the business, it is the best idea to do the forecast demand, plan scenarios, calculate volume discounts, and consider inventory holding costs as the first step. Then one can choose the smallest sum that suits their business best.

What is the difference between MOQ and EOQ?

Economic Order Quantity (EOQ) is another formula used to determine the perfect amount of inventory to hold in a warehouse so a supplier doesn’t waste too much on storage but also runs out of products.

MOQ is the amount of a product that a supplier or seller requires a buyer to purchase at the same time. It can cause the e-commerce business to acquire more inventory than they need in one go, leading them to be far from their EOQ.

When should minimum order quantities be applied?

While speaking of a manufacturer who needs to make and produce products, then compliance with the MOQ conditions is important to stabilize their bottom line and, above all, to make its production viable.

E-commerce businesses that supply products that are typically sold in kits, such as kitchen utensils, for example, must also have minimum order quotas through packaging or picking to increase their average order value, so they can also look into the MOQ for wholesale business partners.

How do you negotiate a minimum order quantity?

- Try to have a conversation about lower minimum order requirements.

- Think about paying a bit higher unit price in exchange for a lower MOQ.

- Use standard elements, not special ones: the closer you are to the market and to people, the better.

- Use the same elements within all product lines.

- Receive offers from both huge and small manufacturers.

- Buy from a merchant, not directly from the factory.

- Source from surplus stocks.

- Visit the markets of China in person (that’s why a lot of suppliers and sellers start taking Chinese language classes: this is really way more comfortable to speak the same language).

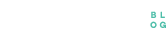

- Look up for a source on AliExpress or DHgate.

- Let somebody else do sourcing and producing for you to make the process more effective.